Where Technology

Meets Ambition

NGO

We are at a stage where the process of establishing the NGO is almost complete, with only the final formal steps remaining. This direction came naturally as our projects grew and required a more structured and stable framework. Becoming an NGO allows us to work in a more organized way, with clear objectives and defined responsibilities. It also gives us greater credibility when engaging with partners, sponsors, and institutions. For our team, this represents a natural step forward, helping us strengthen what we have already built and move toward long-term impact.

EuRoC 2026

Looking ahead to EuRoC 2026, the project will undergo several important modifications that build on the current design while adapting it to new mission and competition requirements. One of the most significant changes is the transition from a liquid propulsion concept to a solid propellant system. This decision is driven primarily by production and integration considerations, as solid motors offer a simpler manufacturing process, higher reliability, and easier handling within the project’s available resources and timeline.

The new prototype, designated Pilot 1, will serve as a dedicated demonstrator for these upgrades. Its primary mission objective is to reach an altitude of 10,000 meters, which represents a substantial step forward in performance and provides a realistic target for validating both propulsion and structural design choices under flight conditions relevant to EuRoC.

To ensure vehicle recovery and post-flight analysis, Pilot 1 will incorporate an active recovery system based on a parachute. This system is designed to deploy during descent, allowing the rocket to be retrieved with minimal structural damage and enabling reuse of key subsystems. Recovery capability is especially important for experimental flights, as it supports iterative development and detailed inspection after launch.

In terms of onboard instrumentation, the new prototype will include temperature sensors and a GPS module. These sensors will allow real-time or post-flight monitoring of the rocket’s thermal state and trajectory, providing valuable data on both propulsion performance and environmental conditions throughout the flight. This data will be used to validate simulations, improve thermal management strategies, and refine future designs.

The development, production, and ground testing of the new solid propellant are scheduled to be completed by the end of February. This milestone is critical, as it will allow sufficient time for integration tests, static firing, and system-level verification before flight operations begin.

An additional enhancement planned for Pilot 1 is a modular avionics bay designed for rapid reconfiguration. This will make it possible to add or swap sensors, update flight computers, or test alternative recovery algorithms without major structural changes. Combined with improved data logging and telemetry capabilities, this approach turns Pilot 1 into a flexible experimental platform rather than a single-use vehicle, supporting continuous learning and performance optimization as the project moves toward EuRoC 2026.

EuRoC 2025

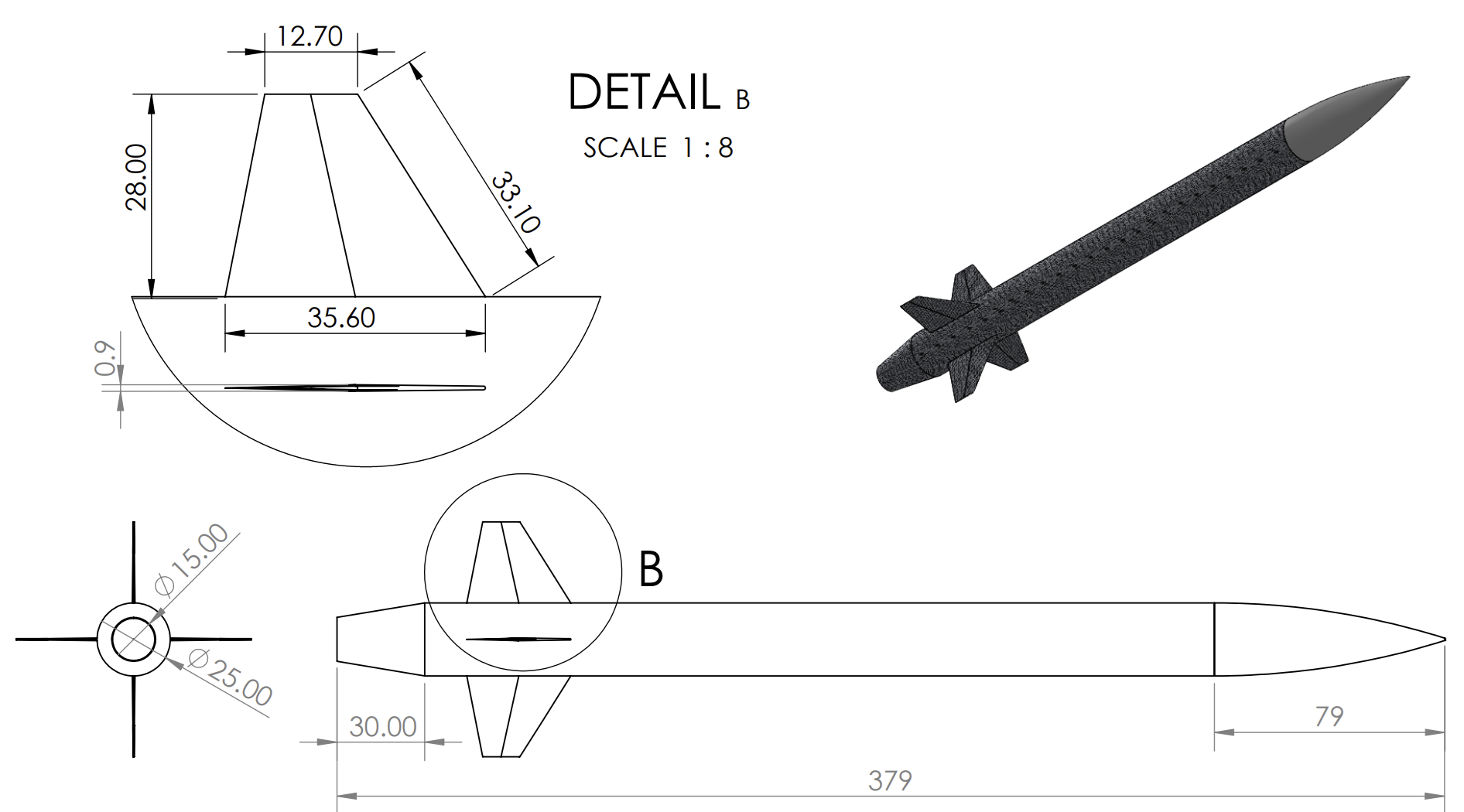

In this discussion, I would describe the project as the structural and geometric design of a small-scale launch vehicle developed as a three-dimensional CAD model in SolidWorks. The project focuses on a cylindrical rocket body intended for educational or experimental aerospace applications. From the beginning, the design approach emphasizes dimensional accuracy, ease of manufacturing, and compatibility with standardized payload interfaces.

From a geometric point of view, the project is based on an axially symmetric cylindrical structure, with a constant external diameter along most of its length. This choice is deliberate, as it supports aerodynamic stability during ascent and helps reduce drag by avoiding sudden changes in cross-section. All dimensions are defined in centimeters, following engineering drawing conventions, and are selected to ensure compatibility with small-scale launch systems and typical competition constraints.

Internally, the rocket body is sized to house a modular payload assembly while preserving enough wall thickness to guarantee structural rigidity. The relationship between internal volume and external diameter represents a balance between payload capacity and mechanical strength, allowing the structure to withstand axial loads, vibrations, and short-duration stresses encountered during launch.

The SolidWorks model includes multiple orthographic views and a sectional view that clearly show key features such as wall thickness, internal clearances, and interface regions. A detailed, enlarged view is used to highlight areas of mechanical importance, particularly payload retention zones and internal shoulders, where dimensional precision is critical.

All dimensions are annotated using consistent tolerancing conventions, making the design suitable for reproducible manufacturing with standard fabrication techniques. The use of explicit decimal tolerances ensures that any deviations introduced during machining or additive manufacturing remain within acceptable limits, maintaining proper alignment between the rocket body and the internal subsystems.

Although no specific material is assigned in the project, the geometry is compatible with commonly used aerospace and prototyping materials, including aluminum alloys, composite tubes, and high-strength polymers. The constant cross-section and the absence of complex features make the design appropriate for both subtractive manufacturing and additive processes. Surface finish requirements are intentionally left flexible, allowing post-processing to be adapted to aerodynamic or structural needs, and the overall simplicity supports rapid design iterations in experimental environments.

From a systems integration perspective, the rocket body acts as the main structural backbone of the launch vehicle. Its internal dimensions allow payload modules, avionics, and deployment mechanisms to be integrated without extensive secondary structures. The cylindrical form supports concentric stacking of components, which helps distribute loads uniformly along the longitudinal axis. In addition, the lack of external protrusions minimizes aerodynamic disturbances and reduces the risk of asymmetric loading during ascent, an important consideration for small-scale rockets.

The project follows standard engineering documentation practices within SolidWorks, including clear use of scales, projection views, and complete dimensional definition. These choices ensure that the design can be interpreted unambiguously by manufacturing personnel or collaborators. Clear guidance on scale usage and the avoidance of manual scaling further reduce the risk of dimensional errors when the drawings are shared or reproduced.

Functionally, the rocket structure serves both as a protective enclosure and as a load-bearing element. During ascent, it must resist axial compression from propulsion and bending moments generated by aerodynamic forces. The uniform geometry and centralized mass distribution contribute to predictable structural behavior. At the same time, the internal layout supports reliable payload deployment, ensuring separation without interference from the surrounding structure during critical mission phases.

Overall, the project defines a structurally efficient and geometrically coherent rocket body suitable for small-scale aerospace missions. Through careful control of dimensions, tolerances, and overall form, the design achieves a balance between simplicity, functionality, and adaptability, providing a solid foundation for experimental launch activities and reliable payload integration.

CanSat 2024

CanSat project development, telemetry, and flight campaign from 2024.

This project presents the design, development, and testing of a modular CanSat-based atmospheric data collection system developed for the Romanian CanSat and Rocketry Competition. The proposed system introduces an unconventional multi-probe architecture, consisting of a primary CanSat carrier and three autonomous slow-descent sub-probes, herein referred to as disk probes. The mission aims to improve spatial resolution in atmospheric measurements by dispersing multiple sensing units over a defined volume of airspace during descent.

The primary scientific objective of the mission is the acquisition of environmental data related to atmospheric pressure, temperature, and pollution concentration across a three-dimensional region. Unlike traditional CanSat missions that rely on a single descent vehicle, this system deploys multiple sub-probes to enable vectorial analysis of atmospheric parameters. By correlating simultaneous measurements from spatially separated probes, the system facilitates the reconstruction of pressure gradients, temperature differentials, and pollutant flow vectors. Potential applications include environmental monitoring, meteorological modeling, and low-cost atmospheric surveying for civilian and research purposes.

The mechanical architecture consists of a lightweight aluminum main canister housing three disk-shaped sub-probes fabricated primarily from biodegradable PLA using additive manufacturing techniques. The design prioritizes mass efficiency, compact stowage, and reliable deployment. During launch, the disk probes are stacked concentrically within the main tube. Following apogee, a time-delayed spring mechanism ejects the sub-probes into free fall.

Each disk probe incorporates a spring-actuated deployable wing, designed as a slightly asymmetrical biconvex airfoil. Upon release from the confinement of the main tube, the wing deploys automatically, converting vertical descent into a controlled autorotative motion. This aerodynamic mechanism reduces terminal velocity and stabilizes descent by transforming gravitational potential energy into angular momentum. The resulting slow, rotating fall enables extended data acquisition time and spatial dispersion.

Each disk probe functions as an independent sensing and communication unit. The onboard electronics are centered around an Arduino Pro Mini microcontroller, which manages sensor data acquisition, processing, and transmission. Environmental sensing is achieved through a BMP280 temperature and pressure sensor and an MQ135 gas sensor capable of detecting variations in air quality parameters such as CO₂ concentration. A NEO-6M GPS module provides positional data, enabling post-flight reconstruction of probe trajectories and spatial correlation of measurements.

Wireless communication between the probes and the ground station is implemented using HC-12 RF transceivers operating in the 433 MHz band. Each probe transmits data packets at five-second intervals on a dedicated frequency channel to avoid interference. Power is supplied by individual Li-ion batteries, dimensioned to support extended operation well beyond the expected descent duration.

The embedded software is responsible for sensor polling, data formatting, and serial transmission over the RF link. Data acquisition occurs in real time, with measurements stored temporarily onboard and transmitted periodically to the ground station. Ground support equipment consists of multiple receiver units connected to computers that log incoming data streams for subsequent manual aggregation and analysis. This distributed reception approach aligns with the system’s multi-probe philosophy and ensures redundancy.

Testing Methodology and ValidationValidation of the system involved extensive mechanical and electronic testing. Mechanical tests focused on deployment reliability, descent stabilization, and structural integrity under impact conditions. Controlled drop tests from heights of approximately 20 meters were conducted to evaluate wing deployment timing and descent rates, targeting a velocity range of 6–12 m/s. Electronic testing verified sensor accuracy, RF transmission reliability over distances up to 1 km, and system robustness under battery-powered operation.

Results demonstrated high reliability of the electronic and communication subsystems, with sensor data closely matching reference meteorological sources and packet loss rates remaining within acceptable limits. Mechanical testing informed iterative design changes, leading to the adoption of the final disk probe architecture optimized for stability and survivability.

ConclusionThe proposed multi-probe CanSat system represents a scalable and cost-effective approach to atmospheric data collection. By leveraging spatially distributed slow-descent probes, the project extends the analytical capabilities of traditional CanSat missions and demonstrates the feasibility of vector-based environmental sensing within severe size and mass constraints.

EuRoC 2026

EuRoC 2025

CanSat 2024 & 2023

Mentors

-

Hirian Răzvan

Technical Mentor

University Professor

-

Alex Muresean

Senior Advisor

Doctorand in Quantum many-body theory in condensed matter physics

Team Leaders

-

Lucas Toma

Project Leader

4th Year Student, Faculty of Physics, Engineering Physics Specialization. International experience at TSRI Taiwan, student at 2 faculties, native English speaker, exceptional verbal skills and passionate about promoting science.

LinkedIn -

Cătălin Ardelean

Technical Leader

Student at the Faculty of Physics, specializing in Computer Physics and Engineering Physics. Works in the engineering field and active in student associations.

LinkedIn -

Dragoș Pintilei

Electronics Leader

4th Year Student, Faculty of Physics, Engineering Physics Specialization. Class Representative. International experience at TSRI Taiwan and Japan. Experienced in competitions and volunteering, thesis work in electronics.

LinkedIn -

Teodor Dinu

Materials Leader

Former National Chemistry Olympiad participant, graduate of the Faculty of Physics, Engineering Physics Specialization.

LinkedIn

Active Members

-

Andreea Condrat

3rd Year Student, Faculty of Physics

-

Diana Condurache

Team Member

-

Rares Bota

3rd Year Student, Faculty of Physics, Physics-Informatics Specialization

-

Stefan Cojocariu

Master's Student in Computational Physics

-

Stroia Radu

Team Member

-

Furdui Andreea Parascheva

2nd Year Student, Faculty of Physics, Engineering Physics Specialization

-

Onica Nicolae

1st Year Student, Faculty of Physics, Engineering Physics Specialization

-

Vasiu Larisa Maria

1st Year Student, Faculty of Physics, Medical Physics Specialization

-

Ștefan Pavel

1st Year Student, Faculty of Physics, Engineering Physics Specialization

-

Sarah Maria Morușca

1st Year Student, Faculty of Physics, Medical Physics Specialization

-

Serban Rotariu

-

Roxy Giurgiu

Team Member

Alums

-

Matrix Alexandru

Master's Student

Pursuing Master's degree in Nuclear Physics at Bucharest University

-

Tudor Aducesei

Former Student

Former student at Technical University of Cluj

Development Timeline

- ADDED New member recruitment opened for December 2025 — welcomed additions to the electronics and materials teams.

- UPDATED With the recruitment campaign we also started preparation activities for EuRoC 2026.

- ADDED Leading committee participated at TECIF 2025 (Taiwan‑Europe Chip Innovation Forum) on 27.11.2025 — presentations and industry exchange.

- ADDED EuRoC 2025 preliminary design documentation complete, awaiting committee review

- UPDATED Propulsion research with new findings from ITIM lab collaboration

- ADDED Three new team members to electronics and materials engineering divisions

- ADDED Completed propulsion research documentation with simulations and theoretical models

- UPDATED Website with technical documentation section

- FIXED Corrections to EuRoC application materials after technical review

- ADDED EuRoC 2025 preliminary design documentation drafted

- UPDATED Partnership agreement with Ion Ursu physics research laboratory finalized

- ADDED Initial research into solid rocket motor design and manufacturing

- ADDED Decision to participate in EuRoC 2025 competition

- UPDATED Team structure with new research divisions

- FIXED Final revisions to CanSat 2024 documentation archive

- ADDED CanSat 2024 competition completed – 2nd place finish

- UPDATED Final technical report and documentation submitted

- ADDED Partnership discussions with ITIM laboratory initiated

- ADDED Completed electrical schematics for CanSat 2024 entry

- UPDATED Sensor integration with optimized power management

- FIXED Communication system reliability issues from 2023 design

- ADDED Final technical report submitted for CanSat 2023

- UPDATED Team decision to participate in CanSat 2024

- ADDED Initial design improvements based on 2023 performance analysis

- ADDED Electrical schematics for CanSat 2023 competition finalized

- UPDATED Team formed as RedShift Aerospace

- ADDED CanSat 2023 competition completed – 4th place finish

Contact

Interested in collaborating, research, or innovation? Reach out and let’s build something ambitious together.